Vokes Streamline Insulating Oil Treatment Plants have been manufactured for over 80 years and are in service (mainly in the treatment of Transformer Insulating Oil) with power generating companies, transmission and distribution authorities in numerous countries worldwide.

Time and a wide variety of geographically harsh environments have proven that Streamline Insulating Oil treatment Plants are extremely reliable, easy to maintain, efficient and economic to operate.

Here at Oldfilter we can identify and support a wide variety of spare parts and filters for almost any Vokes transformer Oil Reconditioning system. Simply provide us with as much information as you can from the name plate (see example below) and what you are looking for.

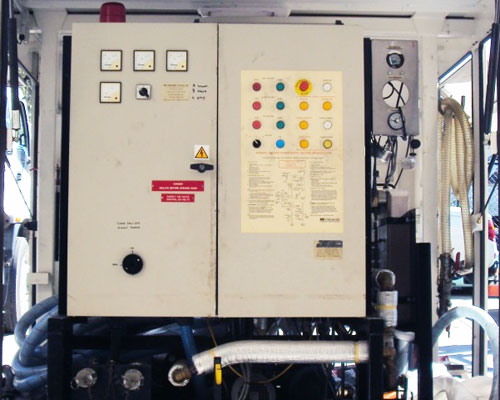

Vokes Streamline transformer oil filtration plant

Vokes C6000, Vokes C4000, Vokes C2000 Oil Purifier

Vokes Streamline manufactured two main families of transformer oil Purifier. The Vokes Streamline “C-range” of oil filtration plant was based around a disposable filter element. Models in this range included Vokes C6000, Vokes C4000 and C2000 model. These models were available in both fixed and mobile versions across a number of different operations voltages and frequencies.

Replacement filters For Vokes C6000, Vokes C4000 and Vokes C2000 Oil Purifier

We can support worldwide distribution of filter elements for these models, common filter element part numbers for these plants include part number 6390039, 6371140, 6390278, 6390277, C6390039, C6371140, C6390277 and C6390277. In order to ensure you get the right filter element for your Vokes Oil purifier please talk to us.

Vokes Streamline transformer oil filtration plant

The Vokes Streamline SL range of Transformer oil treatment plants used a very unique method of oil treatment utilising a filtration method called “edge filtration”. This led to the development of a very unique filter element

The filter rod consists of a very specialised filter media (similar in appearance to paper) cut into discs and loaded on a central carrier with a hollow centre. The transformer oil flowed through the edges of the discs into the centre of the rod and upwards to the clean side of the filter element. These filter rods were built into a filter pack which consisted of 6 of these unique rods. Adjustment of the filter was allowed for by means of a spring mechanism. The number of filter pack required is dictated by the specific plant in question. If you require replacement Vokes Streamline filter elements rods then talk to us.

There were a number of different models of Vokes SL oil treatment plants, the most common being:

- Vokes SL40 – filtration Capacity 4,000 litres per hour

- Vokes SL20 – filtration capacity 2,000 litres per hour

- Vokes SL10 – filtration capacity 1,00 litres per hour

These Oil filtration plants were built in both mobile and fixed version across a number of different supply voltages and frequencies. We can support an extensive range of spare parts for these plants such as filter elements, heater elements, and seals and pump spare parts. If you have part numbers such as 6364014/30 or C6364014/30, 6364014/34 or similar please talk to us for replacements.

Vokes Stream-Line De-Acid Modules

These modules were developed by Vokes for use in conjunction with both their “C-range” and “SL range” of transformer oil filtration plants. These modules were used in the treatment of acidity in insulating oil. If you require replacement filter elements for a Vokes De-Acid module please contact us.

Older Models of Vokes Transformer Oil Purifier

Before the introduction to the Vokes SL range of Oil purifiers Vokes (introduced in the 1970’s) there were and still are a number of even older models of Vokes Transformer Oil Purifier. These machines were known as the HT and MT series of transformer oil filtration machine. If you have a HT125, HT250, MT250, HT1000, HT2000 and you require replacement filter paper then we can support your requirement. It is not uncommon to find these machines still in operation worldwide.

AVCAT Vokes Filters, K-type Filters

K5527, K8927, K11927 were models of an aviation fuel filters (sometimes referred to as K-type plants or absorber vessels) designed specifically to remove water from aviation fuel. These were generally found on seagoing vessels with a helipad on board and are still used today. The filtration method used is similar to that used on the SL model. The use of this type of AVCAT fuel filter date back to the 1950’s when Vokes originally designed these aviation fuel filters in conjunction with the MOD.

Why treatment of Transformer Insulating Oil is necessary (Oil regeneration)

In order to understand why oil regeneration is necessary it is first necessary to understand the role of Insulating oil in transformers. Insulating oil in transformers is required to perform a multitude of tasks. The most obvious use is that of an insulant between points of high electrical stress in the transformer, thereby preventing arcing between components of high potential. In addition to providing the insulating function, transformer insulating oil provides a protection to the windings of the transformers from the effects of moisture in the atmosphere and also acts as a cooling medium. One further very important role is its ability to help remove, (by recirculation through a filtering plant), any contaminants in the insulating oil. Contaminants in insulating oil include water, carbon, gases, fibres, rust oxide, acid and sludge to name a few.

Rust can enter transformer from dirty drums used in filling the transformer with oil, pipework connected to the transformer or corrosion from within the transformer itself.

Water is absorbed from the atmosphere as a result of the breathing action that takes place every time the equipment is switched off and cools down. It can also be the result of defective paper insulation during which time further moisture will be shed into the oil. Water can reduce the Dielectric strength of the oil by anything up to 20%.

Gases are formed from overheating, when extinguishing an arc, or when a transformer is defective or simply from the ageing process of the oil. Solid contaminants in the form of carbon resulting from arcing, paper fibres and metallic oxides which may be generated by corrosion or from cleaning clothes during maintenance on the transformer.

From the very brief overview above one can see how transformer insulating oil can become contaminated and why the need to regenerate the oil is necessary. A deeper and more in depth study of the causes above shows that ultra-fine filtration and a multi stage filtration process is needed to achieve optimum results.